Ceiling Mounted Bridge Cranes And Monorails

Material Handling Systems, Inc. is a leading supplier of Gorbel bridge cranes and monorail systems in Connecticut, Massachusetts, Rhode Island and New York. Whatever industry you’re in, we’ve got the crane solution you need to get it done better, faster, safer.

Bridge Cranes

The most commonly referred to type of overhead crane is a bridge crane. Perfect for medium to heavy lifting, a bridge crane has an elevated parallel runway system with a traveling bridge to move the load forward and backward. The hoist lifts the load up and down, so overall the bridge crane offers four-way maneuverability. It also runs overhead, providing the ability to move loads over aisles and other obstacles.

A Top Running bridge crane runs on a rail installed on top of the runway system, while a Top Runner bridge crane uses a pair of single flange wheels to run right along the top of the runway beam itself, eliminating the need and expense of a rail. An underhung bridge crane runs on the bottom of the runway beam. Underhung, or under-running bridge cranes are used for lighter capacities since they are frequently suspended from the roof and eliminate the need for additional floor column support.

In comparing single girder and double girder bridge cranes, the primary difference is the height that the hoist will lift. Single girder cranes have a lower height, but may be less expensive due to a simpler trolley, quicker installation, lighter runway beams and the need for only one girder.

Below is a general guideline for single girder crane use:

- Up to 7.5

- Up to 10

- Up to 15

- Up to 20

- Up to 25

- Up to 30

- Up to 35

- 80

- 75

- 65

- 60

- 55

- 50

- 45

Monorails

In a monorail system, a hoist and trolley runs along one beam, allowing for only up and down movement with the hook and forward and back movement along the beam. For this reason, monorail systems are highly effective in moving loads from one point to another with great speed and efficiency. Monorail systems can be customized with a curved track and to integrate with other crane systems.

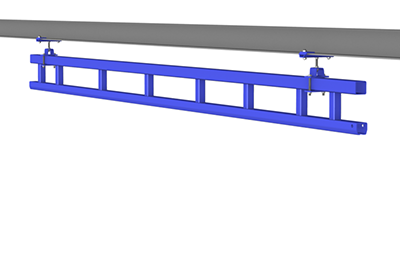

Gorbel Monorails

Features & Benefits

- Steel or Aluminum track

- Free Standing options available

- Enclosed track / easy movement and long life

- Ease of Installation

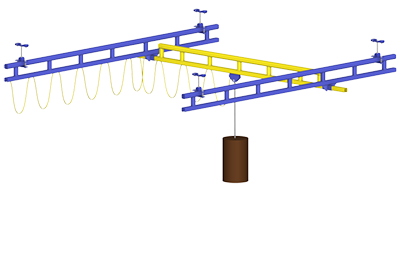

Gorbel Ceiling Mounted Bridge Crane

Features & Benefits

- Enclosed track / easy movement and long life

- Rigid runways / superior load positioning – no movement or “crabwalking” of the bridge

- No support structures so work areas are kept clear of obstruction

- Ease of Installation

- Smooth rolling surface / Easier movement of bridge and trolleys

- Multiple track profiles and spanning capabilities/Adaptable, flexible, and cost competitive

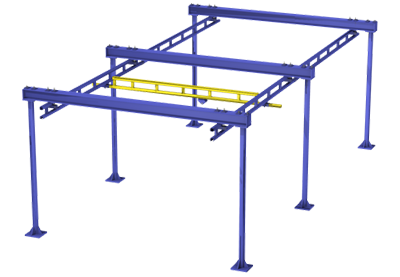

Gorbel Free Standing Bridge Crane

Features & Benefits

- Enclosed track / easy movement and long life

- Rigid runways / superior load positioning – no movement or “crabwalking” of the bridge

- Ease of Installation / install on any standard 6″ concrete floor Smooth rolling surface / Easier movement of bridge and trolleys

- Multiple track profiles and spanning capabilities/Adaptable, flexible, and cost competitive

Located in West Hartford, CT, Material Handling Systems, Inc. is a leading supplier of material handling systems in Connecticut, Massachusetts, Rhode Island and New York. Whatever industry you’re in, we’ve got the solution you need to get it done better, faster, safer. We pride ourselves on offering superior customer service and competitive pricing on all of our products and services. Some of our products include: cranes, hoists, lift tables, conveyors, storage racks, dock equipment, material handling equipment, guarding/fall protection systems and more. We also offer system engineering & design, installation, safety & inspection, and sales/service. If you have equipment or materials that you want to move carefully, please contact our offices at 860-523-4205 or fill out the contact form to discuss how we can help.